Innovation is the only way to beat the established market players because unless a product is either many times better or many times cheaper, the consumers rather prefer to go with well-established brands instead of betting money on newbies. And very few know and follow this philosophy more than the Japanese automobile giant Toyota.

Toyota: The Company

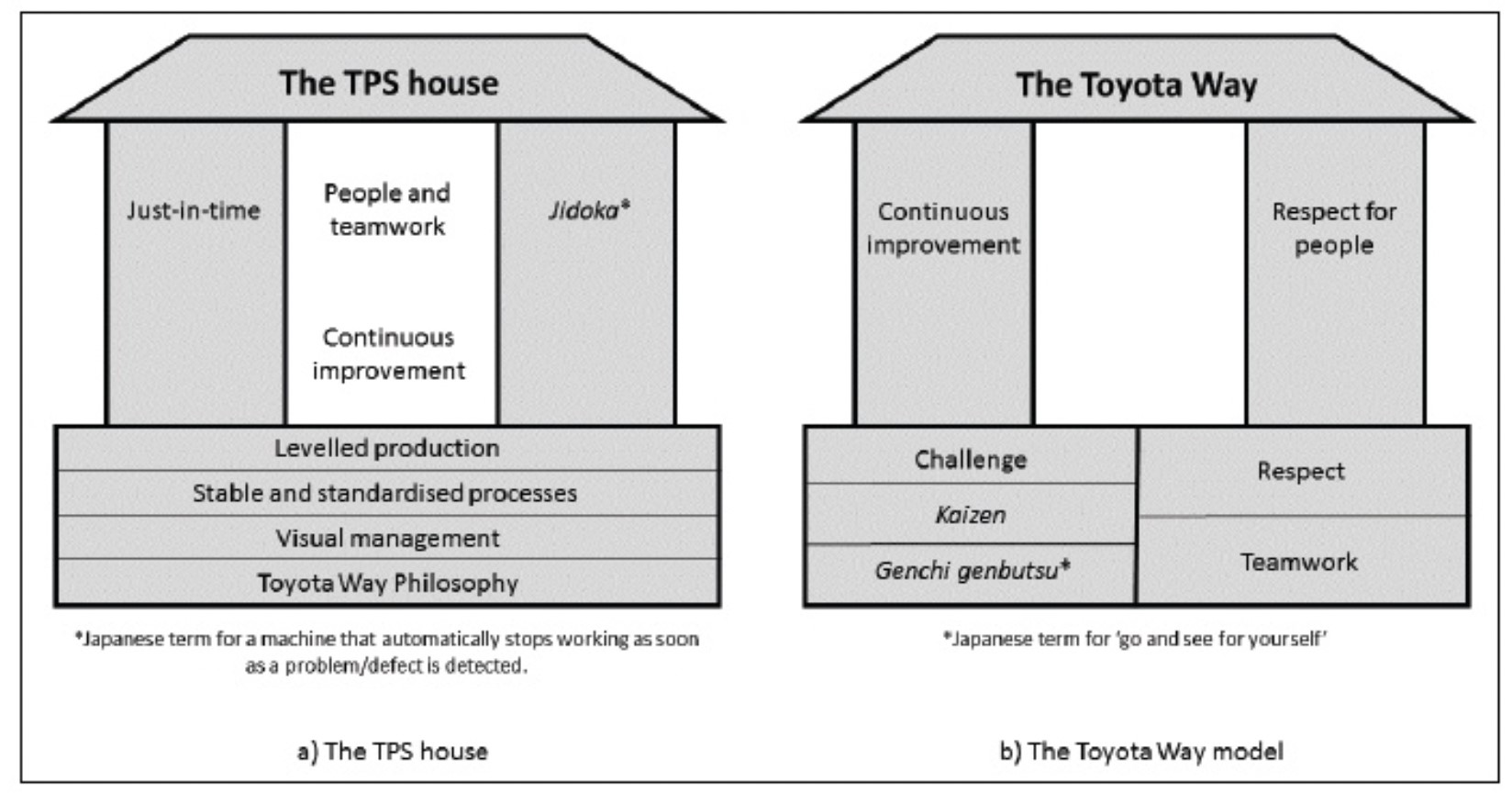

Toyota , the second-largest automobile manufacturer in the world after Germany’s Volkswagen, is known for the Toyota Production System (TPS) through which it raced ahead of American giants like Ford and General Motors. With a revenue of $248.6 billion, Toyota leads the global automotive industry and remains ahead of American and European players in market competition.

The journey of Toyota in the automotive industry starts with post-World War II Japan when the country was devastated in terms of resources as well as morals. The Japanese government decided to double to push towards industrialization despite limited resources at hand and one of the companies that found the favour was Toyota.

In the post-WWII period, Japan and the US became allies and Eiji Toyoda, the head of the Toyota business family, visited the US where they trained at the Ford Motor Company and observed the operations of dozens of other manufacturers. While they learned the efficiency of the American system in the industrial system, they also explored the inefficiencies and the scopes for improvement. For example, Toyoda realized that due to standardization of the production system, the scope for real-time improvement during manufacturing was very little. Also, the huge inventory of the parts put a large amount of capital sitting idle for months.

The Toyota Way

When Toyoda went back home to manufacture a Japanese car, he deployed those learnings and tried to improve Ford’s production system. The new production system came to be known as the ‘Toyota Production System’ (a lean manufacturing practice) that would transform the company into a leader in the manufacturing industry. The management philosophy deployed by the leader is today known as ‘The Toyota Way.’

Today Toyota’s Just in time (JIT) or the lean manufacturing practice is deployed in many industries where a large amount of capital is involved. Going forward, Toyota wants to keep the spirit of taking great leaps through innovative practices alive. While car manufacturers across the world hurry to develop their Electric Vehicles, Toyota has veered off the conventional and commissioned Yamaha Motor to develop a hydrogen-fuelled engine. Toyota wants Yamaha to develop a 5.0-litre V8 engine that is fuelled entirely by hydrogen.

Read More: Toyota has jumped over the EV age to take automobiles to Hydrogen Fuel age

The Future

Presently, our cars and public transport consume way too much oil or natural gas and they also release toxins into the environment doing further damage to the climate change campaign. So, the world is looking at electric vehicles (EVs) as its solution. However, there is a far better solution- hydrogen-powered fuel cell vehicles (FCVs). Toyota has accessed it early and is pushing R&D in this technology.

An FCV is essentially a hybrid vehicle as they have the trappings of both an electric vehicle and a conventional vehicle due to the use of electric energy and a fuel tank at the same time. Toyota and Yamaha take pride in having ‘Motor’ in their names and thus they want to develop a clean engine that still has ‘internal combustion.’

If Toyota’s bet on hydrogen vehicles succeeds, the company would cement its position as a market leader for another few decades. And this innovation-led, feedback-driven improvement philosophy is what keeps the company ahead of its competitors.

Support TFI:

Support us to strengthen the ‘Right’ ideology of cultural nationalism by purchasing the best quality garments from TFI-STORE.COM.