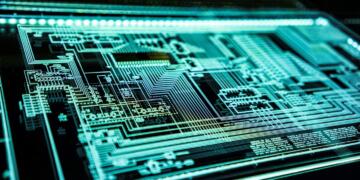

The ‘Make in India’ program of government is producing some very exciting results despite the fact that ‘experts’ are yet to appreciate its success. The hardware part of consumer electronics has lagged behind in our country for decades. So when ‘Make in India’ was started, building capacity in hardware got special emphasis. The result of this special emphasis saved 3 lakh crore rupees in the last four years. Earlier Indian companies used to import whole handset units from the foreign companies. With ‘Make in India’ program, this trend changed and most companies started either manufacturing handsets in the country or importing the parts and assemble them here. Even the foreign companies have started manufacturing mobile phones in India, last month Samsung opened world’s biggest handset manufacturing company in Noida, Uttar Pradesh to produce 120 million phones per year.

“In 2017-18, over 225 million handsets were assembled/manufactured in India, which was roughly 80% of the total market requirement,” the ICEA said in a report. According to India Cellular & Electronics Association (ICEA) estimates local mobile handset manufacturing will generate mobile phones collectively valued at Rs 1, 65,000 crores by 2018-19 and pegs the turnover at 290 million handsets in the same period. The rise in domestic manufacturing of smartphones is not limited to low-end units for India is a major market. Manufacturing units are being set up in the country to export high-end as well as low-end units from the country. First, this trend was seen in the automobile sector where foreign companies set up manufacturing units in India to produce cars which were to be exported to other countries. Now same is happening with mobile manufacturing.

Apple has also started the production of iPhone 6S Plus in Bangalore. Domestic players like Lava, Intex, and Micromax have started production units in India to meet their demands because the import from China is costly and time-consuming. The Chinese manufacturers Xiaomi, Oppo, Lenovo, and Vivo which compete with Indian companies in the low-cost Android phone market have started to manufacture in India. “Most global handset brands and manufacturers are eyeing India, which is the world’s fastest growing Smartphone market, having overtaken the US last year to become the world’s second largest Smartphone market after China,” ICEA chairman & national president, Pankaj Mohindroo, said in a media statement. India is heading towards zero imports in mobile phones and in upcoming years the same response is expected to be emulated in other consumer electronics items. Reliance Jio which is entering in consumer electronics and internet market with an integrated approach is expected to move entire production of Jio handsets in India very soon. The net foreign exchange savings is estimated to be over Rs 60,000 crore. “While CBU imports have come down drastically, import of sub-assemblies and components though has gone up,” ICEA said.

The reason behind this is that the rising per capita income and prosperity in China has increased very rapidly. The Chinese companies find it more efficient to manufacture in India. Foxconn, the Taiwanese manufacturing giant has also signed an agreement with the state government of Maharashtra, Uttar Pradesh, and Haryana to invest five billion dollars. Acer’s spin-off manufacturing arm Wistron announced agreements with Indian government officials to rent land for local production purposes. The Electronic manufacturer, Samsung, Toshiba, Panasonic, and Sony are considering cuts in their investment in China and set up factories in India. So the woes of Chinese manufacturing is not limited to Smartphone companies, it is widespread across all the sectors. As Trump’s ‘Made in America’ rhetoric translates into action, further woes to manufacturing in China is expected. But one thing Indian government should keep in mind that it has to focus more on land and labor reforms if it wants to take advantage of the big manufacturing move over from China.