The Patidars in Gujarat want job reservations. The Jats in Haryana want to be classified as backwards too in order to gain access to government jobs & have displayed that they aren’t afraid to use violence to achieve the status of a “backward community”. Now the Kapus in Andhra Pradesh want reservation, with Kapu community leader Mudragada Padmanabham, 64, leading the charge against the Andhra Government. Their demand is clear, nothing less than Backward Class (BC) status and reservation for the community is going to satisfy them. There is little room for manoeuvre for Chief Minister N Chandrababu Naidu as the Kapu community forms 27 per cent of AP’s population a vote bank which Naidu cannot afford to lose.

The main reason why more and more communities are seeking the “Backward” status is the lack of jobs in India.

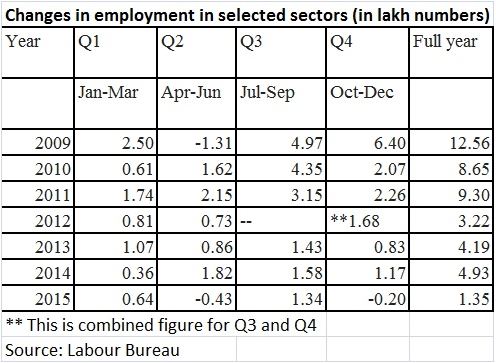

We may be the fastest-growing economy in the world, but we are simply not delivering enough jobs for everyone, precisely 12 million people every year, entering the labour market. As per the latest figures released by the Labour Bureau, no new jobs were created but there was actually a decline of 20,000 jobs across eight labour intensive sectors in the December quarter of 2015.

As Indian companies race to cut their costs they are heavily focusing on in an effort to cut their costs are heavily focusing on automation, take the example of the automobile industry which is one of the main job creators in India-Robots have begun to take over an array of functions from humans at car plants in India. The Ford Sanand plant actually has 453 robots in the shop floor, with up to 90 per cent of the work automated, Volkswagen India has 123 robots at its Pune plant while Hyundai Motor India, the subsidiary of the Korean carmaker, has 400 robots at its factory in Chennai. The entire body shop, most of the paint shop and parts of the final assembly line in these plants are now automated. Not to be left behind, Indian automobile makers such as Maruti Suzuki, Royal Enfield, Mahindra & Mahindra and Tata Motors have increased the levels of automation in their newer plants. Robots are performing functions ranging from welding to foundry operations to laser applications.

Manufacturing becoming more complex, quality and safety standards becoming more stringent and consumers who have become far more conscious about safety, want more features, but are unwilling to compromise on prices are being cited as the main reasons behind the rapid automation drive on automobile companies.

Even the IT sector, which gave India the title of “back office of the world, the IT majors are concentrating on automation and not jobs. A recent example of it is Wipro deciding to use Holmes, an artificial intelligence platform to do the job of 3,000 engineers in order to cut costs.

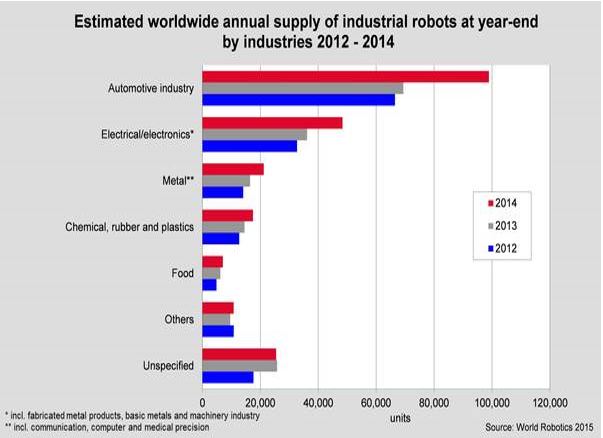

In fact, automobile and IT industries are not the only industry where automation is rising, according to a study by the International Federation of Robotics, use of robots is rapidly increasing in almost every sector.

Sales to all industries, except for automotive and electrical/electronics, increased by 21% in 2014. Between 2010 and 2014, the average growth rate per year was 17%. The respective growth rate for the automotive industry was 27% and for the electrical/electronics industry 11%. This is a clear sign that not only the main customer industries (automotive industry and electrical/electronics industry) but also other industries have increased robot installations considerably in recent years. The robot suppliers have been reporting a significant increase in the number of customers in the past years. However, the number of units ordered by these customers is often very small.

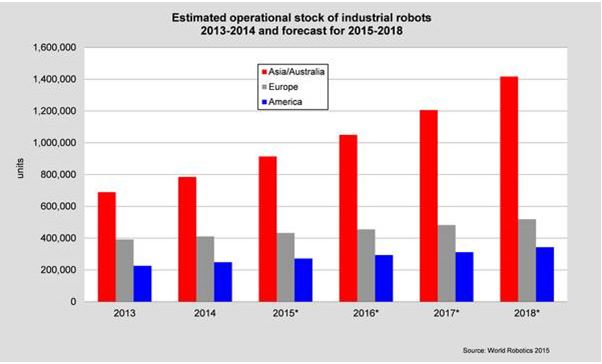

Furthermore, from 2016 to 2018, robot installations are estimated to increase again, at least by 15% on average per year (CAGR): about 10% in the Americas and in Europe, and about 18% in Asia/Australia. Total global sales will reach about 400,000 units in 2018.

Between 2015 and 2018, it is estimated that about 1.3 million new industrial robots will be installed in factories around the world, most of them in Asia.

It will be naïve to say that automation is the only reason why India hasn’t been able to create many jobs, we are still paying the price for the failure of successive central and state governments on the primary and vocational education front.

While India needed a large number of primary & vocational education centres in order to create a healthy and well educated workforce, a prerequisite to industrialization, India’s elites were busy creating IIT’s and other institution of higher educations which enabled only a few to gain the necessary skills necessary to enter into the labour market.

According to the latest NSSO survey findings, the situation is so bad that just 2.2% of those between 15 to 59 years age group received formal vocational training while 8.6% in the same age-group received non-formal vocational training, reveals a government survey. This means around 90% of the people did not receive any kind of vocational training. The survey also reflected that the passing down of hereditary skills, self-learning and ‘on-the-job’ learning continue to generate more skilled workforce than country’s formal vocational training establishments.

Prime Minister Modi faces a huge challenge & needs to act on war footing if he wants to supply every Indian entering the Job market with a Job. In the second, and final, part of this series we will discuss what measures should the government of India take in order to provide every Indian entering the labour force with a job.

Sources:-

1. http://www.firstpost.com/business/where-are-the-jos-mr-modi-2731002.html

2. http://timesofindia.indiatimes.com/business/india-business/Only-2-2-got-formal-vocational-training-NSSO-survey/articleshow/49107369.cms

3. http://auto.economictimes.indiatimes.com/news/industry/man-vs-machine-robots-are-replacing-workers-in-auto-plants-in-india/49991064

4. http://www.ifr.org/industrial-robots/statistics/